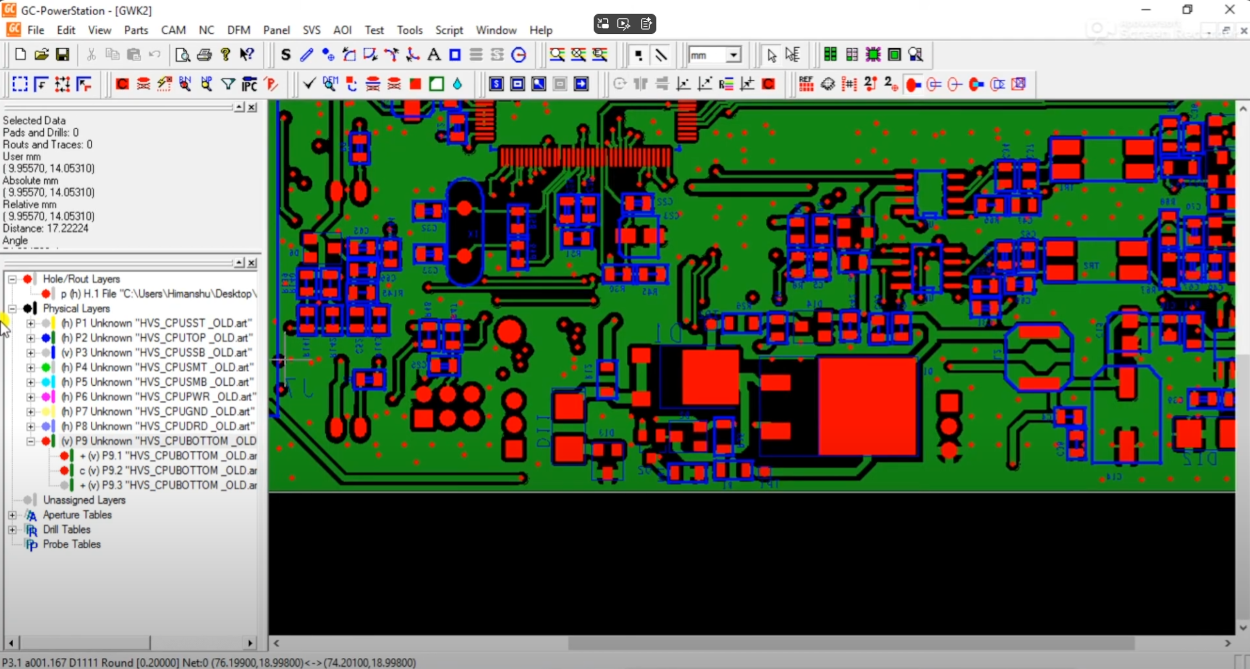

Precision CAM Visualization for PCB Professionals Across Asia Pacific

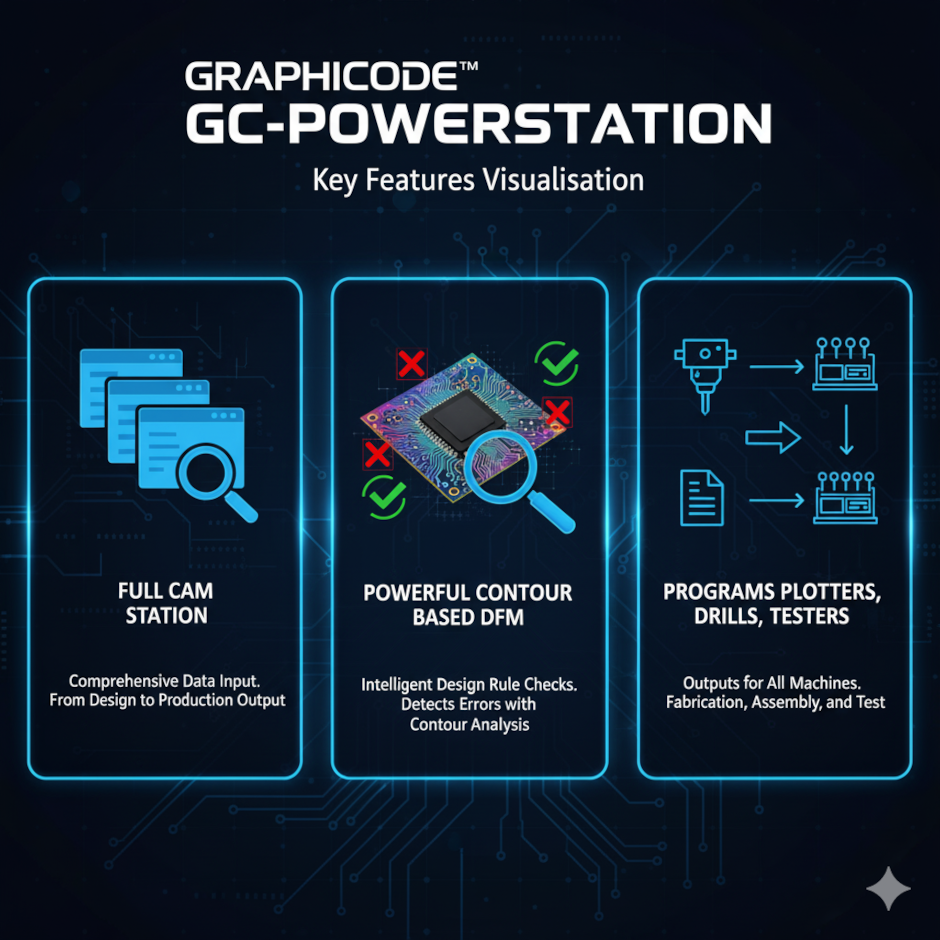

GC-PowerStation

Engineered for manufacturers, engineers, and QA teams, GC-PowerStation delivers pinpoint accuracy in Gerber file analysis and CAM validation. Emtec Solutions brings this industry-standard platform to Asia Pacific, empowering users to detect design flaws early, streamline production workflows, and ensure flawless PCB output—before a single board is fabricated.