GC-CAM Edit: Advanced CAM Software for Precision PCB Manufacturing

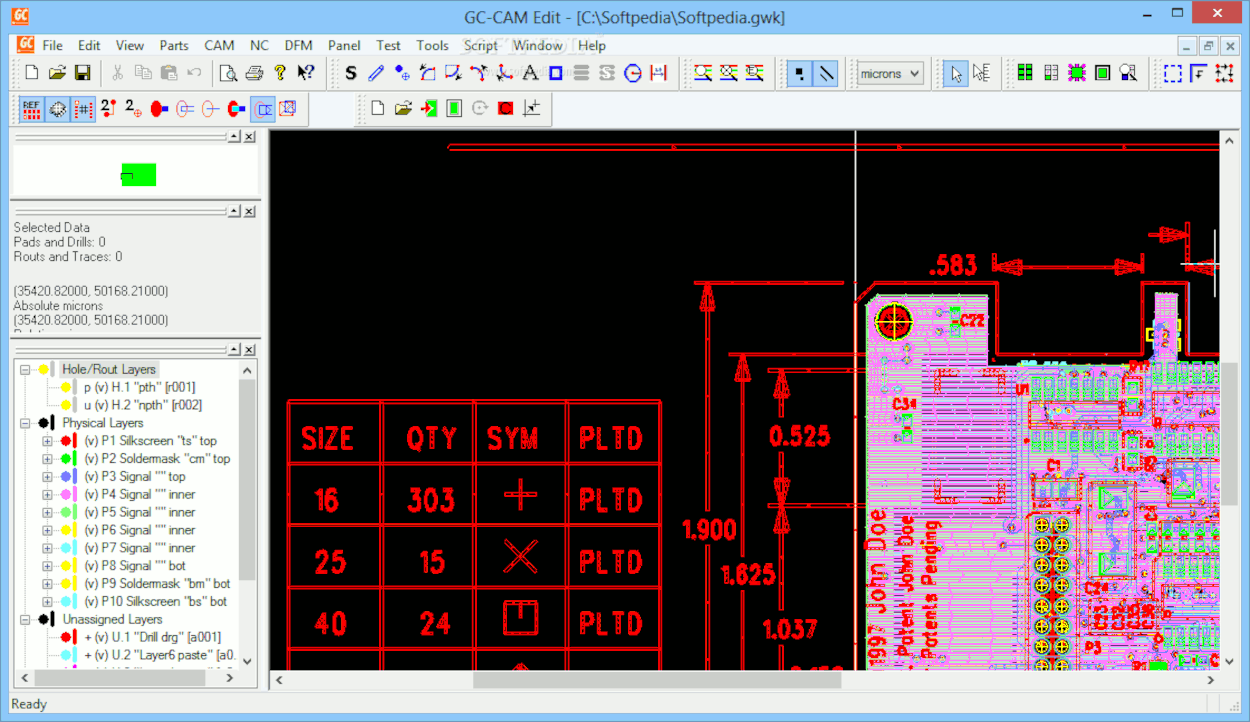

GC-CAM Edit meets the needs of PCB designers and CAM operators who require convenient design modification capabilities. It features all the powerful panelization and editing tools necessary for PCB photoplotting, drill and rout, stencil manufacturing, and basic design modification.

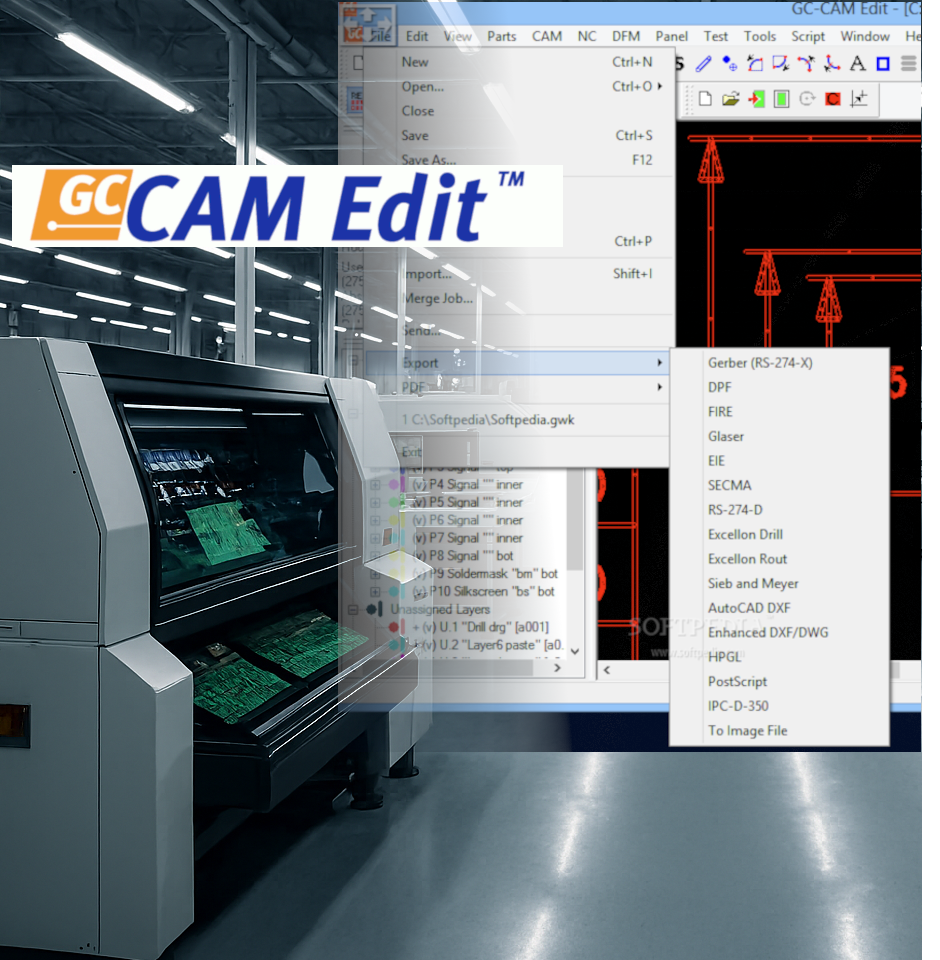

As the authorised distributor of GC-CAM Edit from GraphiCode, Emtec Solutions Pte Ltd proudly offers one of the industry’s most trusted CAM editing platforms for precision PCB manufacturing. Built for engineers, fabricators, and QA specialists across Asia Pacific, GC-CAM Edit empowers users to inspect, modify, and validate Gerber and drill data with pinpoint accuracy—eliminating costly errors before they reach the production floor.

Designed to support complex editing workflows and advanced DFM checks, GC-CAM Edit reads and processes all standard manufacturing formats including Gerber RS-274X, Excellon, DXF, and HPGL. Its intuitive interface, layer control tools, and fabrication-ready output make it an essential asset for any team seeking to streamline production, reduce rework, and ensure flawless board fabrication from prototype to volume.